Wet Alarm Valve: Enhancing Fire Protection Systems with Effective Water Flow Control

In fire protection systems, wet alarm valves play a crucial role in ensuring prompt response and efficient water flow during emergencies. These valves are designed to detect and control the flow of water in sprinkler systems, minimizing the risk of fire-related damage to properties and saving lives. This article explores the significance of wet alarm valves, their operation, and the benefits they offer in maintaining reliable fire suppression systems.

Understanding Wet Alarm Valves

Wet alarm valves are essential components of automatic sprinkler systems. They serve as a barrier between the water supply and the sprinkler pipes, allowing water to flow only when a fire activates one or more sprinkler heads. The valve remains closed under normal conditions, ensuring that water does not enter the system prematurely. However, when the system’s heat-sensitive sprinkler heads detect a fire, the wet alarm valve automatically opens, releasing pressurized water into the sprinkler pipes. This controlled water flow helps suppress the fire, preventing its spread and minimizing potential damage.

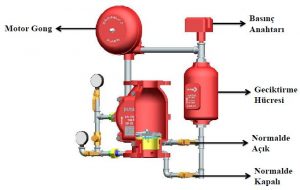

Operating Principle and Components

The wet alarm valve consists of several key components that enable its effective operation. At its core lies a clapper assembly, which prevents water from entering the sprinkler pipes by sealing the valve’s water inlet. This assembly includes a clapper, a clapper seat, and a clapper chamber. Additionally, there are a water motor gong, a water motor alarm, and a water motor alarm bypass. The water motor gong provides an audible alarm signal, while the water motor alarm bypass allows for testing and maintenance without activating the entire sprinkler system.

Benefits of Wet Alarm Valves

The use of wet alarm valves offers several significant advantages for fire protection systems. Firstly, they ensure the controlled release of water, minimizing water damage and reducing potential downtime after a fire incident. Secondly, the immediate response triggered by wet alarm valves helps to suppress fires in their early stages, limiting their impact and protecting lives and property. Furthermore, wet alarm valves are reliable and efficient, providing a robust fire protection solution for a wide range of applications, including commercial buildings, warehouses, industrial facilities, and residential complexes. Lastly, these valves are designed to withstand harsh environmental conditions, ensuring their long-term functionality and durability.

Maintenance and Testing

Regular maintenance and testing are crucial for the proper functioning of wet alarm valves. These valves should be inspected periodically to ensure that they are in good working condition. Maintenance activities may include cleaning, lubrication, and testing of the clapper assembly, as well as inspection of gaskets and seals for any signs of wear or deterioration. Additionally, conducting flow tests and monitoring water pressure are essential to verify the valve’s response and the overall integrity of the fire protection system.

Wet alarm valves are fundamental components of fire protection systems, providing reliable water flow control and prompt response during fire incidents. By effectively regulating the release of water in sprinkler systems, wet alarm valves play a vital role in minimizing fire-related damages and safeguarding lives. Their robust construction, compatibility with various applications, and ability to withstand harsh conditions make them an ideal choice for commercial, industrial, and residential settings. Regular maintenance and testing are essential to ensure the optimal performance of wet alarm valves, ensuring their readiness to combat potential fire hazards effectively. Incorporating wet alarm valves into fire protection systems significantly enhances their overall effectiveness and reliability.