Diesel Fire Pump is one of the most effective fire extinguishing methods developed against negativities such as power cuts in fires. Unlike electric fire pumps, diesel pumps continue to operate in the event of a power outage. Another advantage of these fire pumps, in which diesel engines are used, is that they can operate automatically.

It is extremely important to set the ambient temperature correctly in fire pumps where diesel engines are used. The recommended ambient temperature for this type of pump is 10 degrees Celsius. Some fire pumps also use mixed systems consisting of electrically driven components with diesel engines.

As it is known, a fire pump is an equipment that transfers water from the water source to which it is connected to the fire extinguishing system at a pre-calculated pressure and feeds the system. Uncontrolled fires can cause loss of life and environmental damage as well as financial losses. For this reason, fire pumps are the machines that prevent the fire from growing and help to get an effective result in a short time by activating at the initial stage of the fire in the firefighting.

The fire pump provides the supply of water to the fire extinguishing systems with constant flow and pressure. Fire pumps supply the sprinkler system, fire hose system and hydrant system with pressurized water uninterruptedly. Despite taking all kinds of safety precautions, there is always a risk of fire. Fire pumps are of vital importance in order to minimize the fire hazard as well as the damages that may occur in the event of a fire.

DIESEL FIRE PUMP AND ITS KEY FEATURES

Diesel Fire Pump; The mechanical structure of the fire extinguishing system, the area to be used, the location of the water source, the flow rate, density and risk level of the water are among the main criteria to be considered in the selection of the pump. For example, vertical turbine type pumps are used in cases where the water source to flow to the pump is below the suction point, and horizontal suction pumps are used in other cases. In addition, the flow and head calculations of the fire pump that the system needs should be selected by making hydraulic calculations. These calculations are made by experts in line with national and international standards, according to fire hazard classes. The fire pump, which is selected with correct calculations according to the system and location, prevents unwanted situations by showing full performance in case of a possible intervention.

- Diesel engines to be used for the Diesel Fire Pump must be reliable, first class and designed for fire extinguishing systems.

- It should be equipped with the necessary mechanism so that it can be operated for at least 30 minutes a week.

- Engine power must have at least more power than the required maximum shaft power.

- Necessary corrections should be made in engine power selections, taking into account conditions such as ambient temperature and altitude.

- Pump-motor connection should be made with flexible coupling.

- There should be an automatic throttle mechanism that will keep the engine speed constant within the range even under closed discharge pressure and maximum load conditions.

- There must be an “overspeed shutdown device” that will stop the engine in case of more cycles than the rated speed.

- There should be a tachometer showing the engine speed for the Diesel Fire Pump.

- There must be an oil pressure gauge showing the engine oil pressure.

- There should be a temperature indicator showing the engine coolant temperature.

- All motor instruments must be installed on a properly secured instrument panel.

- All cables that need to be connected to the control unit must be connected at the factory and moved to a terminal group.

- Starting must be thanks to the battery pack.

- There should be two battery groups, main and backup.

- Battery groups should be selected with twice the power required to crank 6 times for 3 minutes.

- There should be a hand-controlled contactor that provides the voltage of both battery groups manually.

FIRE PUMP SELECTION

Fire pumps have a wide range of uses, from residences to factories, against possible fire risks related to people or the environment. Types of fire pumps developed for residences are used for security and fight against fire in private properties, villas, sites and apartments. Fire pumps, which have different types according to usage area, are installed in areas with high fire risk such as industrial facilities, municipalities, schools, hotels, shopping malls, hospitals, marinas, shipyards, chemical and hazardous material processing facilities, waste facilities and filling facilities. In addition to fire pumps that are permanently installed as part of a system in a closed area, mobile fire extinguishing systems also have pump options integrated behind the water tank. This type of pumps are especially used by disaster-fighting teams in the fight against fire.

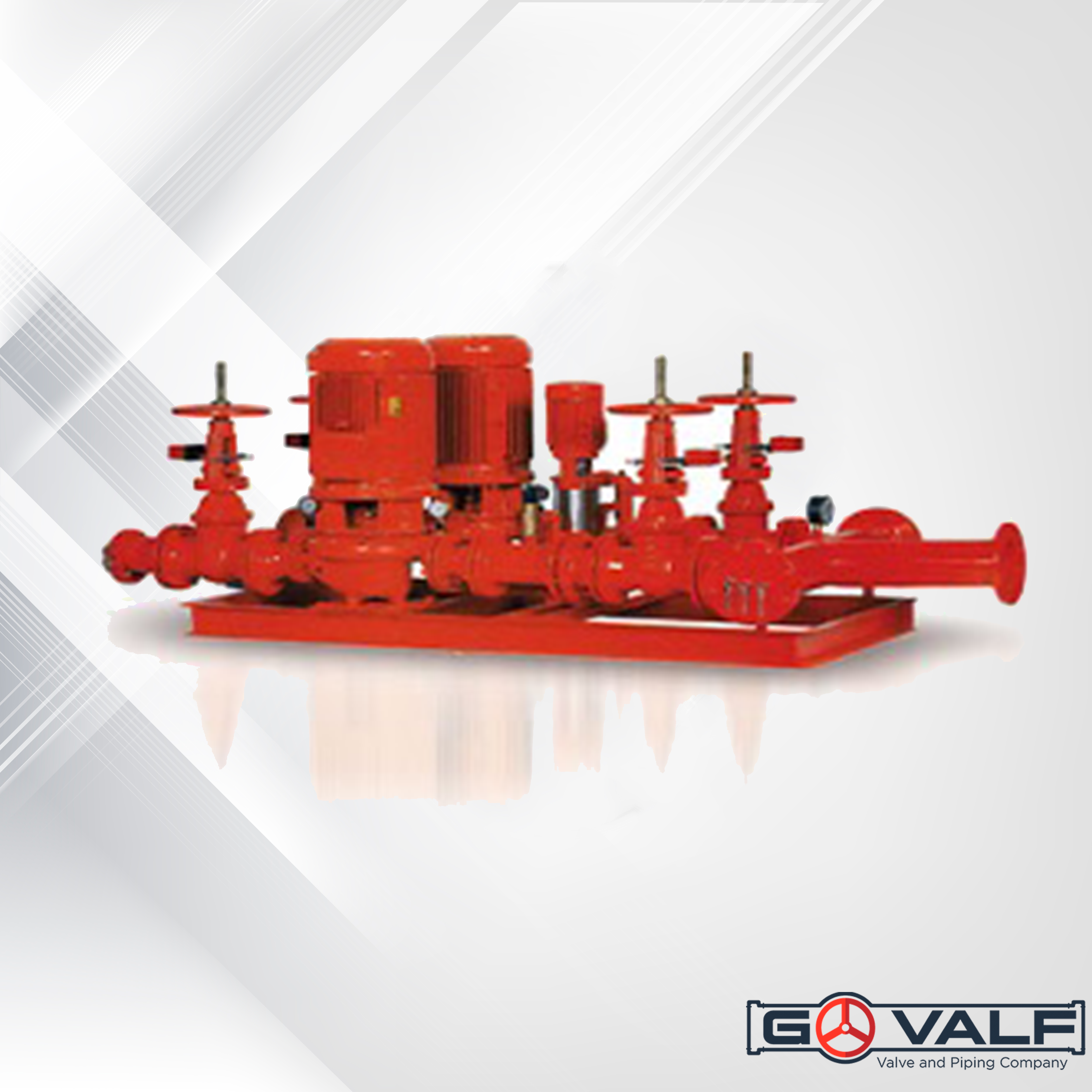

There are different models of hydrophores developed for use in fire. The product varies according to the fuel type and model it has. Varieties usually run on electricity or petroleum fuels. Both fuel types are preferred in these systems, which are mostly used for precautionary purposes. This mechanism includes the main pump and its auxiliaries. Just in case, spare parts are also needed for precaution. Failures in the structures may cause the inability to reach electricity. In this case, efficiency cannot be obtained from a mechanism that works with electricity alone. This means the inability to cope with the fire and serious damage to the facility. Therefore, in preventive mechanisms, the main part and the spare part work with different sources. The main pump is activated first in the system. In case of any malfunction in the main pump, the backup becomes active and provides the required pressure and flow. Models generally have 3 different types. One of them is the centrifugal pump type. These single-stage models are also end-suction. These mechanisms are easy to maintain. Parts such as the impeller can be removed without completely disassembling the installation of the pump. This reduces maintenance and effort. Another variety has a detachable body. They have double suction power and their bodies are horizontal. Models also include line type ones. These single suction products are vertical shaft. The product, which can be maintained and repaired without difficulty, is single-stage. Fire pump prices vary according to the model, material and technical features of the product. The technology used in the products is also among the factors affecting the price.

ABOUT GO VALVE

As the GoValf team, we have been bringing together mechanical installation supply solutions in accordance with current technologies in Turkey and neighboring countries since 2009 with our customers. While we offer the most exclusive brands of Turkey and the world to our customers at the most affordable prices, we add new ones to our solutions every day.

Our departments today;

- Plumbing Equipment,

- Fire Suppression Systems and Equipment

- Pumps and Boosters,

- Heating Solutions,

- Air Conditioning and Ventilation

We offer our customers privileged services from basic to delivery in their projects with our expert teams and nearly 100 brands by classifying them in their fields. Moreover, in our sector where competition is increasing day by day, we have increased our quality and diversity with various products that we manufacture by following the technologies. In addition, we design, cast, manufacture, assemble, test and control the products we produce in our own facilities with our own expert team. Our priority is the peace and happiness of our customers. We serve our customers with the assurance of GoValf. With our understanding of safe, high quality, stable work and competitive prices, we are working with all our strength to be in cooperation not only for today but forever. The trust of our customers in us is our biggest capital. We continue to offer you the most affordable prices and the highest quality services by achieving a healthy cooperation with our suppliers, based on data and information, in harmony with customer requests with engineering solutions. In particular, we carry out the design, casting, production, assembly, testing and check-ups of the products we produce in our own facilities with our own experienced staff. In our sector, where the competition is increasing day by day, we have increased our quality and diversity with various products that we manufacture by following the technologies.